OUR CORE PURPOSE

Through the responsible transformation of the Earth’s natural resources, we help keep people safe, feed the world and enrich lives, every day.

WHAT WE DO

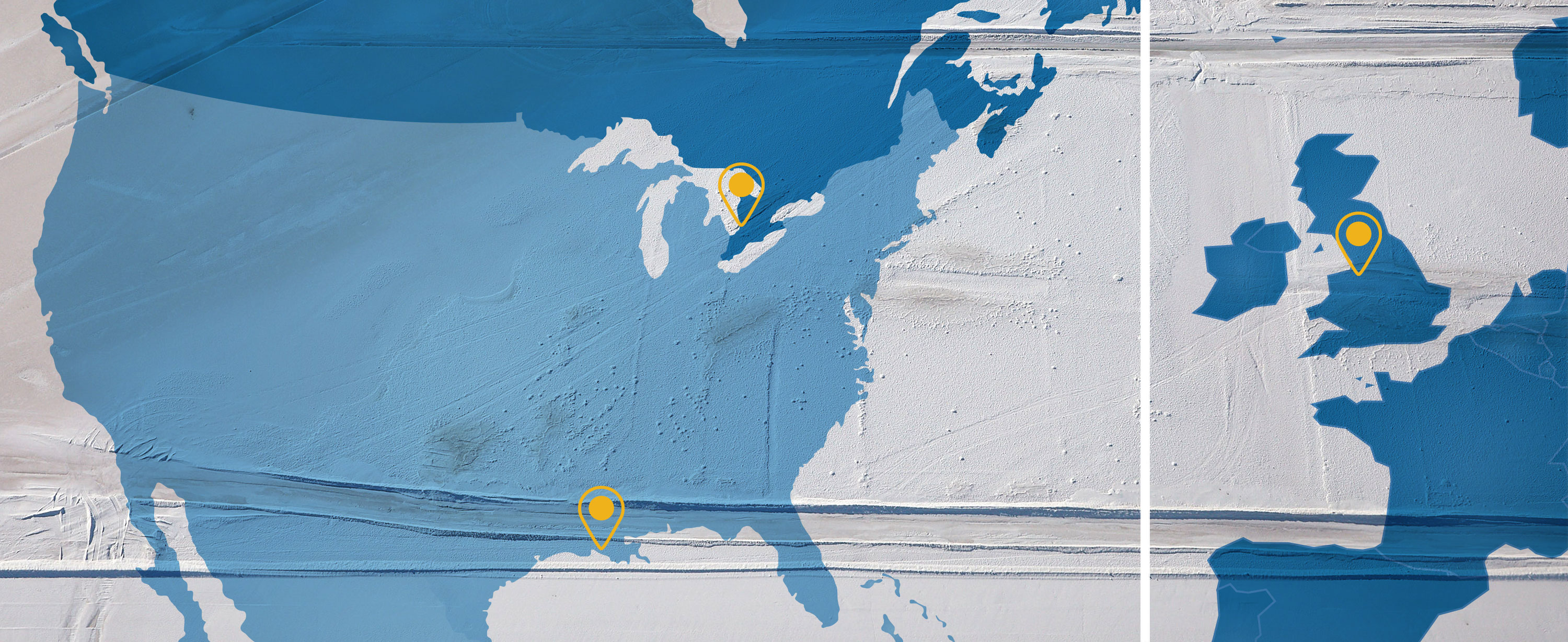

Compass Minerals produces salt, plant nutrients and magnesium chloride for distribution primarily in North America. We also provide secure records storage in a retired mine in the United Kingdom. Products from Compass Minerals serve a variety of applications in industrial, agricultural, commercial and consumer markets.

CORPORATE RESPONSIBILITY

At Compass Minerals, we have a clear vision of our corporate purpose. Through the minerals we mine and harvest and the products we produce, we help keep people safe, feed the world and enrich lives every day. This means building a sustainable company. This means ensuring safety throughout our operations for our employees and the communities in which we operate. This means stewardship of the resources we manage and working to minimize or mitigate our environmental impact.

Compass Minerals has locations in the U.S., Canada, Brazil and the U.K. Use the key below for location details and information.

Compass Minerals employs a number of production methods to develop quality products. Select a method below to learn more.

Compass Minerals offers a variety of salt brands tailored to a range of industries from deicing and industrial to food grade, water care and beyond. Below is a complete list of the Compass Minerals salt brands. For more information on a salt brand, click the logo to be redirected to its website.

Resources

Compass Minerals’ company headquarters in Overland Park, Kansas, is home to our senior management team and is a hub of activity for finance, operations, corporate services and the salt and plant nutrition business units of the company. This headquarters is also a support for our geographically diverse team of sales managers — a team that spans across the U.S., Canada, Brazil and the U.K. and which has centralized offices in Mississauga, Ontario, and Repentigny, Quebec.

Our Brazilian operations are headquartered in São Paulo and operate in two primary businesses — agribusiness and chemical solutions for industrial processes. Just like our Overland Park headquarters, our São Paolo headquarters is another support for our widespread team of sales managers.

- 9900 W. 109th Street

Overland Park, Kansas 66210

913.344.9200 - Av. Paulista, 1754, 3º andar – Cerqueira César

CEP 01310-920 – São Paulo – SP

Compass Minerals has two innovation centers for supporting and developing the North and South American portfolios. The centers employ over 50 scientists dedicated to formulation, product development, basic research, field trials and other essential work that keeps Compass Minerals at the forefront of our industry.

- North America

Innovation Center

Stilwell, Kansas

U.S.

- South America

Innovation Center

Iracemápolis, São Paulo

Brazil

Compass Minerals’ five mechanical evaporation plants produce high-purity, fine- and coarse-grained salt products in packages and in bulk for commercial, agricultural and industrial applications.

- Goderich, Ontario

Canada - Unity, Saskatchewan

Canada - Lyons, Kansas

U.S.

- Nappan, Nova Scotia

Canada

- Wynyard, Saskatchewan

Canada

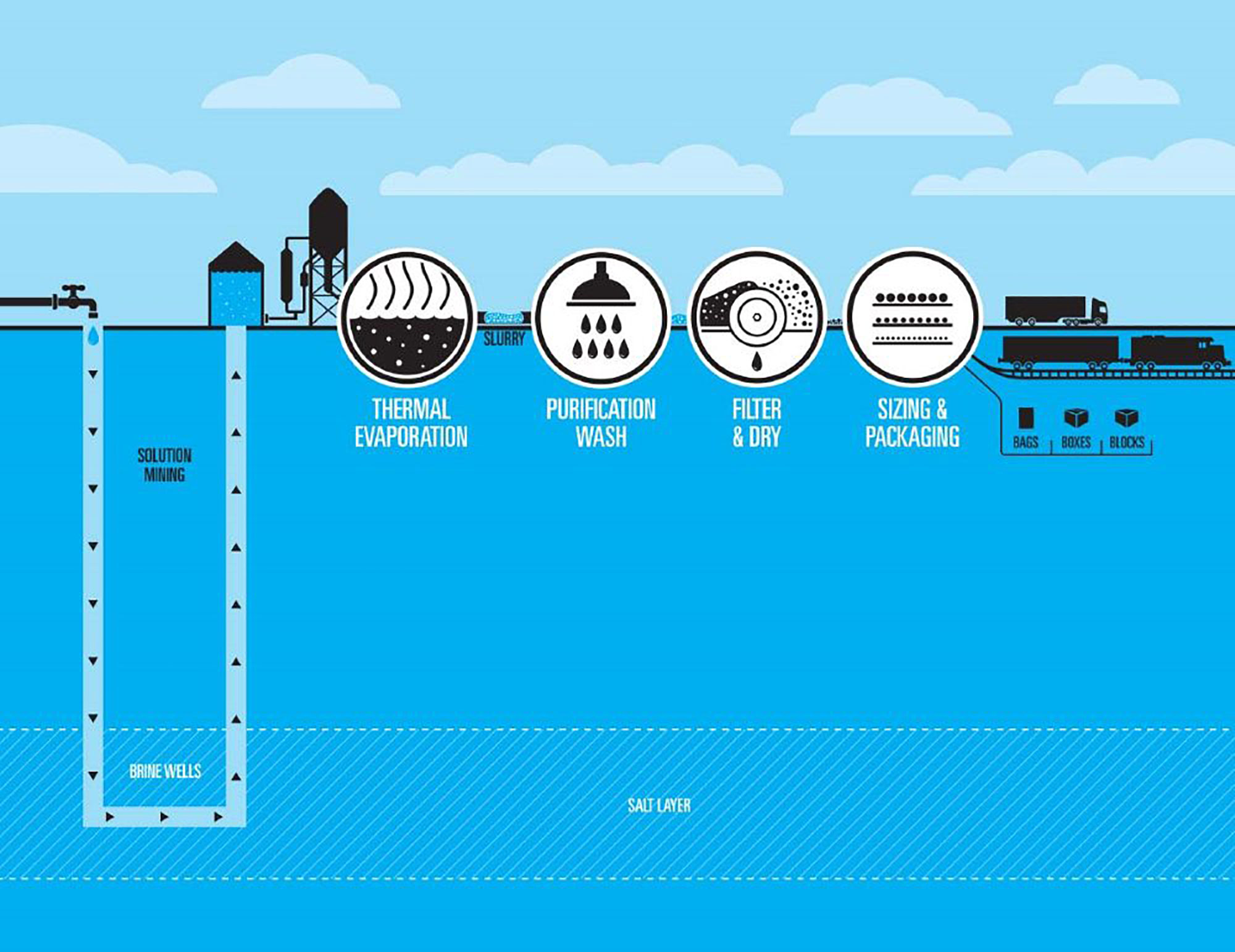

Mechanical evaporation uses high-efficiency processes to yield high-purity salt for consumer, agricultural and industrial applications. We begin by injecting water into an underground salt deposit to create saturated brine. The brine is drawn out and evaporated in a series of large crystallizers. As the water evaporates, salt crystals remain and are then washed to remove impurities. In the final phases, salt is passed through a filter-dryer and then on to a processing area. The end result is a high-purity crystallized salt.

Our three U.S.-based packaging facilities manage raw materials from our locations across the U.S. and Canada, from consumer deicing and water conditioning salt to bulk deicing for highways and mineral blocks for livestock.

Our production facilities specialize in high-quality products for plant, animal and forest nutrition, chemical products, water treatment solutions and soil fertilizers. Specialized professionals work in our research laboratories using state-of-the-art technology to develop innovative products to meet the growing requirements of international agribusiness and other industries the company serves.

Our Wynyard, Saskatchewan, production facility uses ion exchange (IX) and glaserite processes to produce potassium sulfate (SOP). The IX products are some of the highest-purity SOP products in the world. The glaserite process produces SOP through a chemical reaction of anhydrous sodium sulfate and crystalline potassium chloride. IX-produced SOP is used in many specialty areas including pharmaceutical and food industries, while SOP manufactured by glaserite is generally used as a specialty fertilizer in high-value crops and other industrial uses.

- Igarassu

Igarassu, Pernambuco

Brazil - Jacareí I

Jacareí, São Paolo

Brazil

- Jacareí II

Jacareí, São Paolo

Brazil

- Reluz Nordeste

Marechal Deodoro, Alagoas

Brazil - Mauá

Mauá, São Paolo

Brazil - Suzano I

Suzano, São Paolo

Brazil - Suzano II

Suzano, São Paolo

Brazil - Uberlândia

Uberlândia, Minas Gerais

Brazil - Wynyard, Saskatchewan

Canada

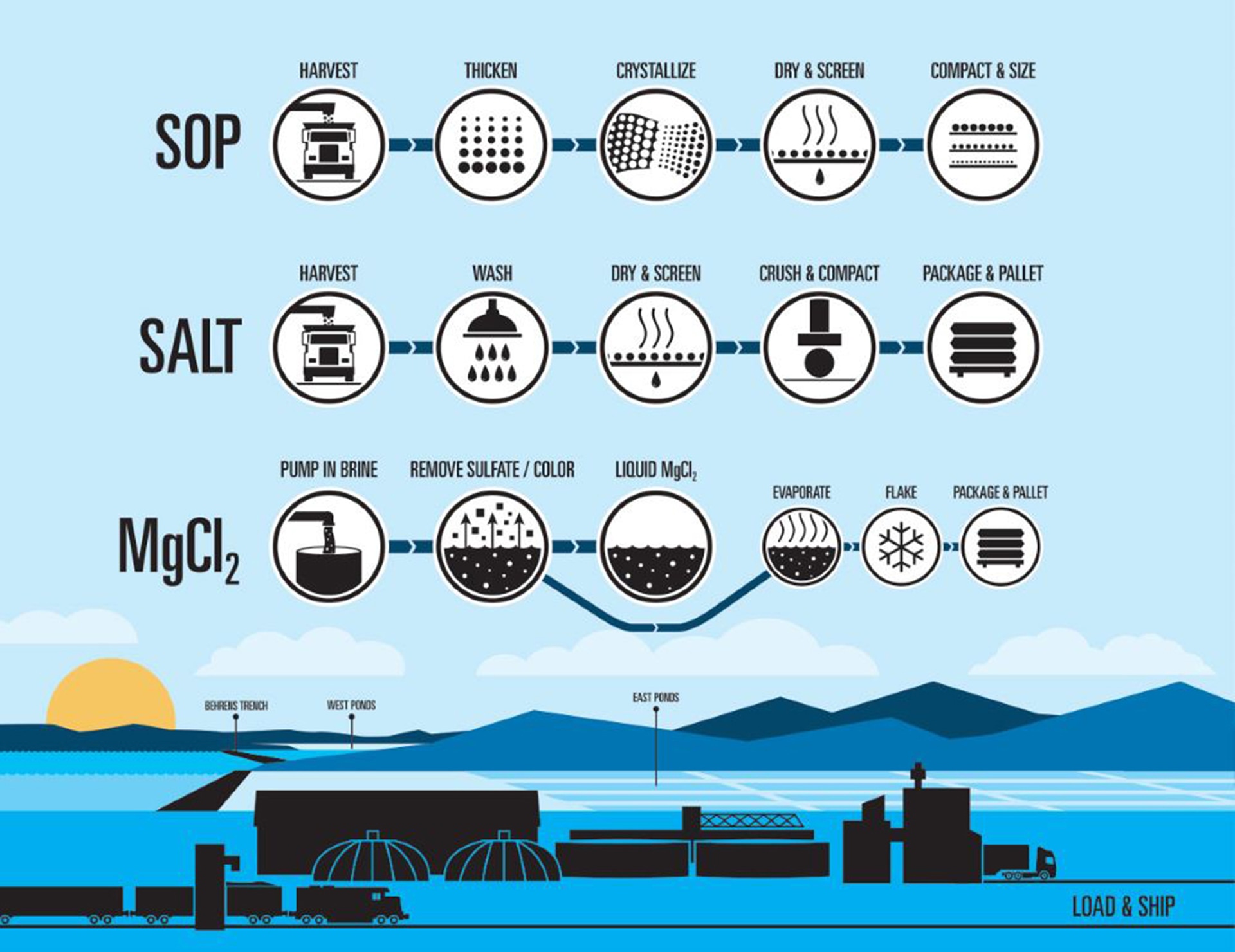

Our 50,000-acre solar evaporation pond complex in Utah produces salt, sulfate of potash (SOP) and magnesium chloride for a variety of uses. It is one of only four locations in the world that can produce SOP from a naturally occurring brine source using solar evaporation. The Ogden location has operated on the Great Salt Lake in Ogden, Utah, since 1968 and became part of the Compass Minerals family in 1993.

Solar evaporation is the oldest and most energy-efficient method of mineral production. At our Ogden, Utah, location at the Great Salt Lake, we draw highly concentrated saline waters from the lake’s most remote areas into very shallow solar evaporation ponds to produce salt, sulfate of potash (SOP) and magnesium chloride. Compass Minerals is the largest SOP and magnesium chloride producer in North America.

Compass Minerals owns two underground storage facilities known as DeepStore. DeepStore has more than 1.8 million square meters of storage space that provides secure storage of items ranging from active records to treasured paintings. One of the more well-known DeepStore customers is The National Archives, for whom DeepStore manages public records.

Compass Minerals has three underground mining locations, one of which is the largest underground salt mine in the world. The rock salt that is mined is either packaged and sold for a variety of uses, or sold in bulk to manufacturers of plastics, detergents, disinfectants and other important products.

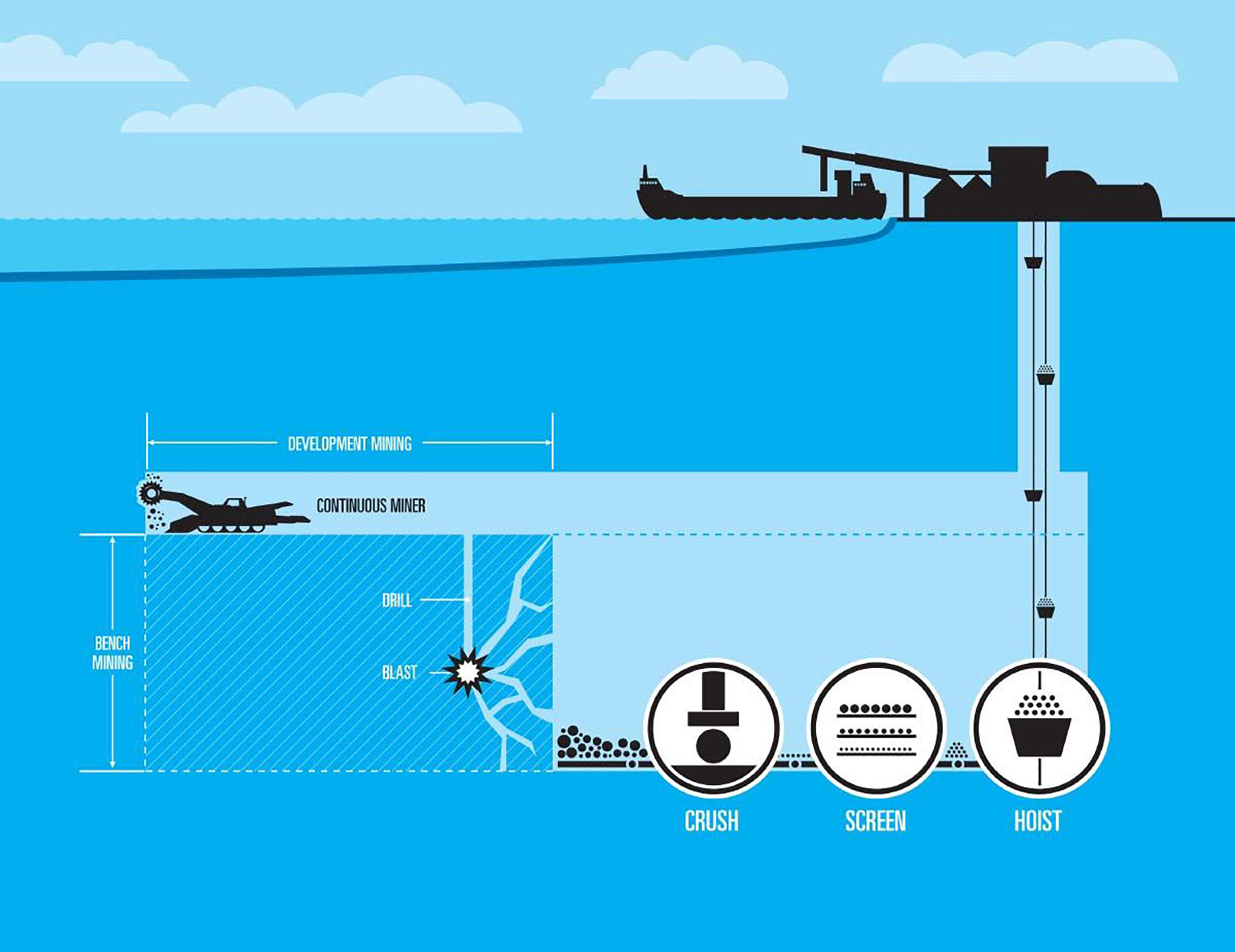

We produce rock salt from underground mines using both continuous mining techniques and drill-and-blast. Our mines have extensive, consistent reserves with decades of remaining production, and our mine in Goderich, Ontario, is the largest rock salt mine in the world. Our rock salt mines are located between 500 feet and 1,800 feet below ground. Whether produced through continuous mining or drill-and-blast, we extract salt from each mine in rectangular “room” sections, leaving behind vast “pillars” of salt to support the mine structure.

CONTINUOUS MINING

The continuous mining method, which we employ at our mines in Winsford, Cheshire, and Goderich, Ontario, is a modern mining technique that has been implemented for improved sustainable operations. It uses state-of-the-art machines with steel cutting picks to shear salt from the rock face, thus avoiding the need for explosives.

DRILL-AND-BLAST

The drill-and-blast mining method, used at our Louisiana mine only, begins by cutting into the rock salt face using specialized equipment. We then drill holes into the face and use explosives to break the salt into large rocks. Front-end loaders and trucks load and haul the salt to a crusher where it is reduced in size, loaded onto a conveyor belt and transported to a mill. The mill screens and crushes the rock salt to the customary size before the salt is hoisted to the surface.